What is a tube furnace? What are the characteristics

Release Time:

Oct 18,2024

Tube furnace, as a common industrial heating equipment, plays an important role in material processing, chemical synthesis and experimental research. It has won the favour of the majority of users with its unique structure and efficient heating performance. In this paper, the definition of the tube furnace, structural characteristics and application areas are introduced in detail.

Tube furnace, as a common industrial heating equipment, plays an important role in material processing, chemical synthesis and experimental research. It has won the favour of the majority of users with its unique structure and efficient heating performance. In this paper, the definition of the tube furnace, structural characteristics and application areas are introduced in detail.

First, the basic concept of tube furnace

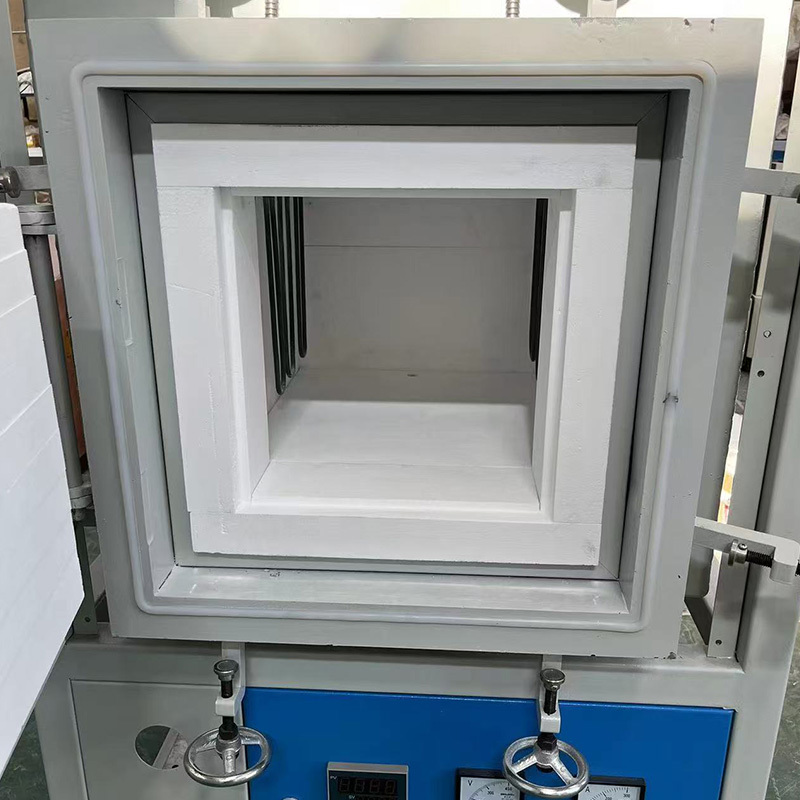

Tube furnace, as the name suggests, is a furnace chamber is a tubular structure of the heating equipment. It usually consists of furnace tube, heating elements, control systems and auxiliary equipment and other components. The furnace tube is the main part of the tube furnace, which is usually made of high-temperature and corrosion-resistant materials, such as quartz, ceramics or metal. The heating element is responsible for providing heat so that the material inside the furnace tube reaches the required heating temperature. The control system is used to accurately control the temperature inside the furnace to ensure the stability and safety of the heating process.

Second, the structural characteristics of the tube furnace

High-efficiency heating: Tube furnace adopts high-efficiency heating elements, such as resistance wire, electric heat pipe, etc., which can quickly convert electric energy into heat energy and achieve rapid heating. At the same time, the material inside the furnace tube is heated evenly by heat radiation and convection, ensuring the uniformity and consistency of the heating effect.

Precise temperature control: Tube furnace is equipped with advanced temperature control system, which can achieve precise temperature control. Users can set the heating temperature, heating rate and holding time according to their needs to ensure that the heating process meets the process requirements.

Compact structure: the tube furnace adopts integrated design, compact structure and small footprint. This allows it to be flexibly arranged in laboratories, factories and other environments where space is limited, improving space utilisation.

Easy to operate: The tube furnace's operating interface is simple and clear, easy to get started. Users only need to control panel or remote control system to achieve the equipment start, stop, temperature adjustment and other operations, greatly reducing the difficulty of operation.

Third, the application areas of the tube furnace

Material processing: tube furnace has a wide range of applications in metal smelting, ceramic sintering, glass melting and other material processing fields. Through precise control of the heating temperature and heating time, it can achieve uniform heating and rapid curing of the material and improve the quality and performance of the product.

Chemical synthesis: In the field of chemical synthesis such as organic synthesis, inorganic synthesis and catalyst preparation, tube furnace also plays an important role. It can provide a stable and controllable heating environment for the chemical reaction, promote the reaction, and improve the purity and yield of the product.

Experimental research: Tube furnace is also one of the indispensable equipment in the laboratory. It can be used to study the thermal properties of materials, the kinetic process of chemical reactions and the synthesis and preparation of new materials. Through the experimental research of tube furnace, it can provide theoretical basis and technical support for industrial production.

Tube furnace plays an important role in many fields with its features of high efficiency heating, precise temperature control, compact structure and easy operation. With the continuous development of science and technology, the performance and application fields of tube furnace will continue to expand, providing more possibilities for industrial production and scientific research.

Keywords:

More information