Optimisation of the heating core of the pearl cotton laminating machine

Release Time:

Oct 11,2024

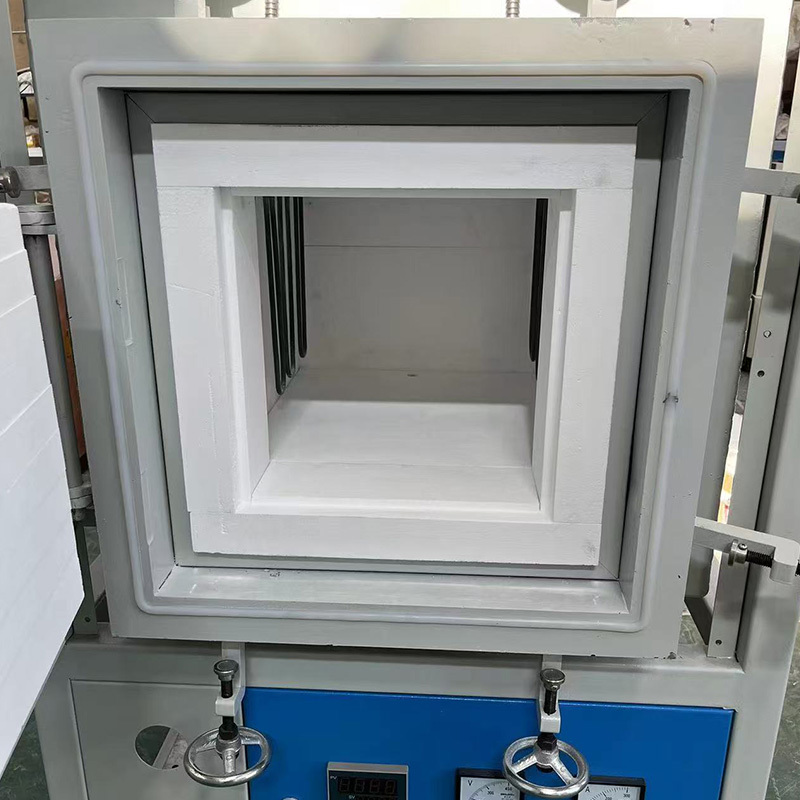

Pearl cotton laminating machine is a commonly used processing equipment, which is usually used to laminate pearl cotton with other materials to enhance the compressive and protective properties of the materials. Among them, the heating core is an important part that plays the role of heating, which affects the effectiveness and efficiency of the whole laminating process. Therefore, it is very important to optimise the heating core.

Pearl cotton laminating machine is a commonly used processing equipment, which is usually used to laminate pearl cotton with other materials to enhance the compressive and protective properties of the materials. Among them, the heating core is an important part that plays the role of heating, which affects the effectiveness and efficiency of the whole laminating process. Therefore, it is very important to optimise the heating core.

Firstly, the material of the heating core should be optimised. Generally speaking, the heating core should choose materials with good thermal conductivity, high temperature resistance and corrosion resistance. Common materials include stainless steel, copper and other metal materials, as well as ceramics and other high temperature materials. According to the specific composite materials and process requirements, the selection of suitable materials can effectively improve the heating efficiency and stability.

Secondly, optimize the structure of the heating core. The structure of the heating core should be reasonably designed to transfer heat uniformly and stably to the composite material. Porous structure or surface openings and other designs can be used to increase the heating area and improve the heat transfer efficiency. At the same time, the surface of the heating core should be surface treated to increase the surface roughness, improve the contact area with the composite material, and then improve the heat transfer efficiency.

In addition, the control of the heating core is also the focus of optimisation. According to the characteristics of the composite material and process requirements, the heating temperature, heating time and other parameters of the heating core should be set reasonably. At the same time, the control system of the heating core should be stable and accurate, able to monitor the heating temperature in real time and adjust the control parameters in time to ensure the stability and reliability of the composite process.

Finally, the maintenance of the heating core is also the focus of optimisation. Regularly clean the ash and impurities on the surface of the heating core to keep the surface of the heating core clean and heat transfer efficiency. At the same time, the connecting parts and electrical wiring of the heating core are regularly checked to ensure the safe and stable operation of the heating core. If there are damaged or aging parts, they should be replaced and repaired in time to ensure the normal use of the heating core.

In summary, the optimisation of the heating core of the pearl cotton laminating machine can improve the efficiency and quality of the laminating process, reduce energy consumption, extend the service life of the equipment, and improve productivity and economic benefits. Through a reasonable choice of materials, optimise the structural design, fine control and regular maintenance measures, you can achieve a comprehensive optimization of the heating core, so that it better serves the production process.

Keywords:

More information