What types of chamber furnace calibration are available

Release Time:

Oct 18,2024

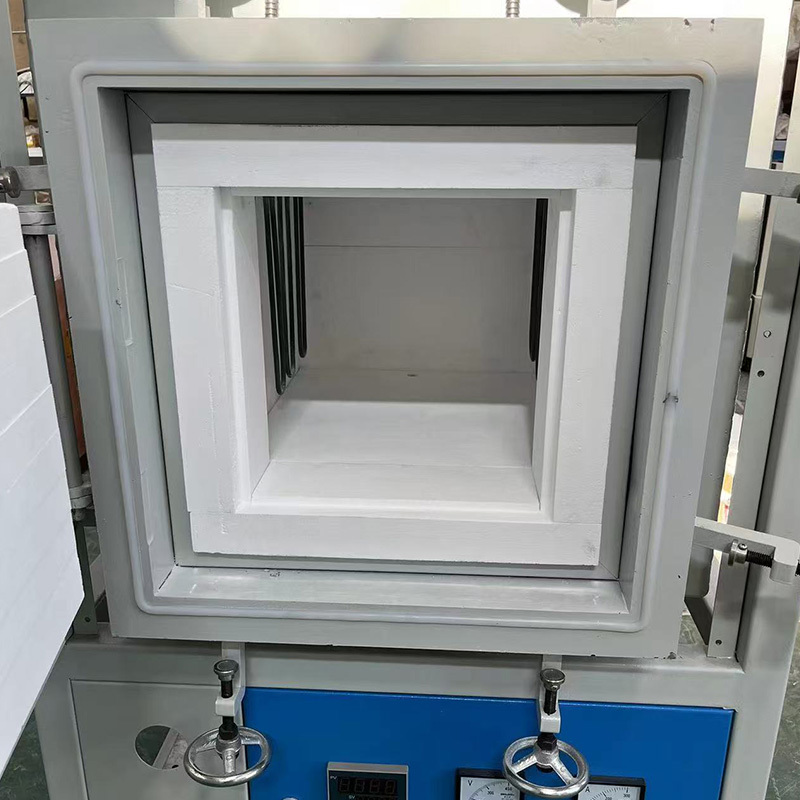

Calibration of chamber furnace to determine the first working area of the furnace, one is to use the ‘chamber size’ as a design parameter; the second is to use the calibration of the customer to provide the ‘size of the working area’ to determine the working area, the following chart (solid line) the size of the schematic.

1, the determination of the work area

Calibration of chamber furnace to determine the first working area of the furnace, one is to use the ‘chamber size’ as a design parameter; the second is to use the calibration of the customer to provide the ‘size of the working area’ to determine the working area, the following chart (solid line) the size of the schematic.

2, the determination of the temperature measurement point

According to the size of the working area of the chamber furnace, design the size of the temperature measurement frame, to determine the 5 temperature measurement points, 1 monitoring point. The 5 temperature measurement points are located in the centre of the work area and the front of the lower left, front on the right and back on the left, back on the right 4 end corners (as shown in Figure 1, 2, 3, 4, 5 points). Monitoring point is located in the temperature control thermocouple end point extension direction of not more than 150mm in the work area, if the centre point from the temperature control thermocouple measurement point extension direction of not more than 150mm, the centre point is regarded as the monitoring point.

3、Selection of temperature calibration device

Temperature calibration device consists of measuring instruments, thermocouples and ancillary equipment, etc., the introduction of the expansion of uncertainty, should be consistent with the calibration requirements of the uniformity of the furnace temperature of the box furnace being calibrated (i.e., the uncertainty value is not greater than the uniformity of the furnace temperature value of 1 / 3).

4, the calibration process

Calibration is usually carried out in the empty furnace. Before calibration, the measuring end of the detection thermocouple will be fixed in the temperature measurement frame of the various temperature measurement points (such as the above figure 1, 2, 3, 4, 5) position, well marked. Then, the temperature measuring frame into the furnace, the thermocouple reference end of the furnace, according to the marking of the serial number were connected to the measuring instrument through the conversion switch. Close the door of the furnace, send electricity to warm up, the box furnace temperature control instrument is set to the required calibration temperature.

When the furnace temperature reaches the calibration temperature, stabilised and start reading. In 60 minutes, every 3 minutes to record the monitoring point, each temperature measurement point and the temperature control instrument display temperature, a total of 20 tests. Each recording of the temperature displayed at the monitoring point, each temperature measurement point and the temperature control instrument should be completed within 1min.

Keywords:

More information